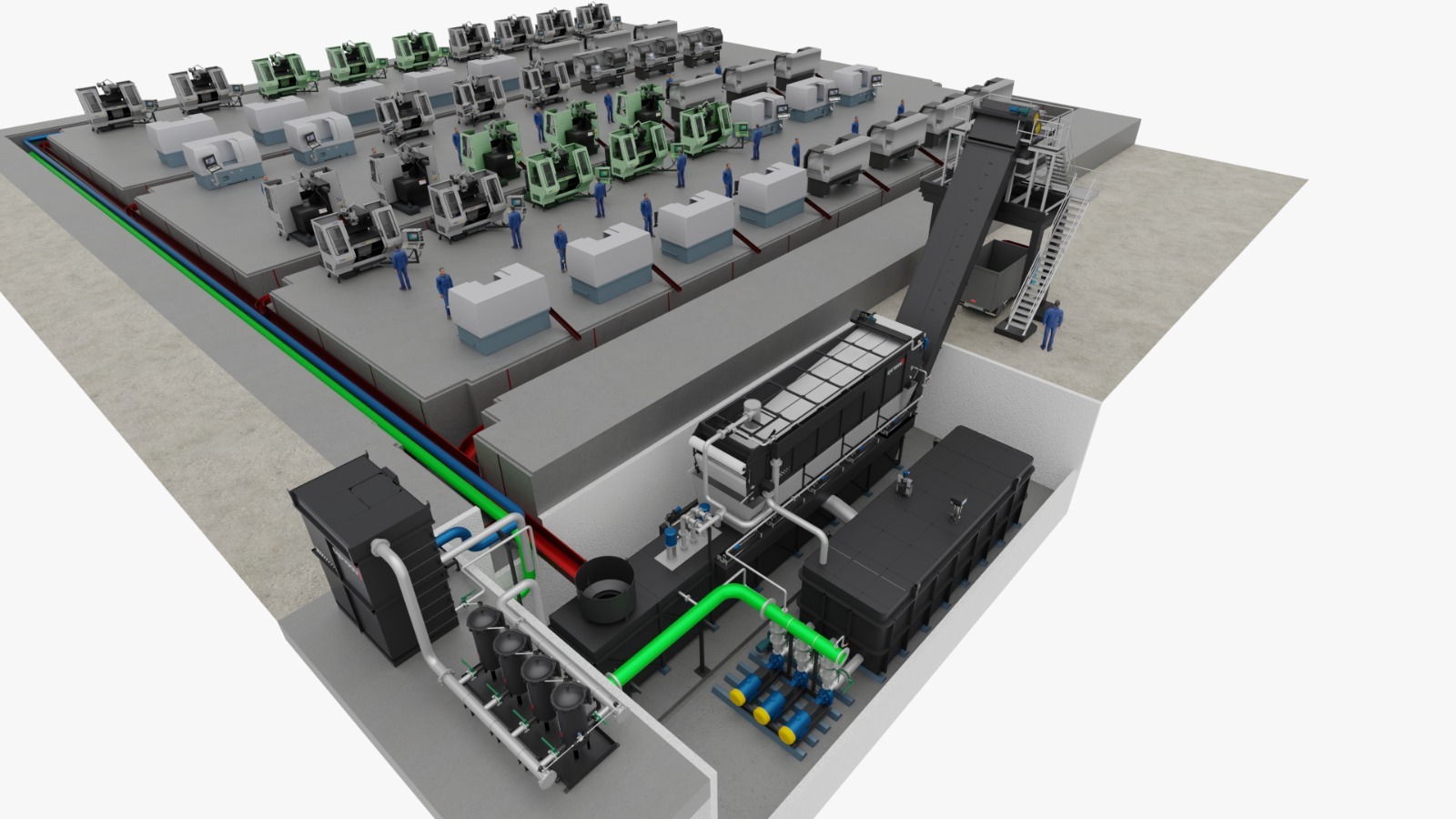

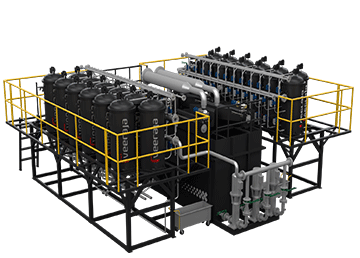

A Centralized Filtration System is basically a Common Filtration System for a group of machines. Hence a centralised filtration can cater to a small group of machines or the complete shop. It is generally a combination of various Coolant Filtration System Products and Accessories.

A Centralized Filtration System is the most effective and efficient ideology in Coolant Filtration System and Cutting Oil Filtration System.

A Centralized Filtration System has huge benefits over a Individual Filtration System.

Read MoreA Centralized Filtration System is basically a Common Filtration System for a group of machines. Hence a centralised filtration can cater to a small group of machines or the complete shop. It is generally a combination of various Coolant Filtration System Products and Accessories.

A Centralized Filtration System is the most effective and efficient ideology in Coolant Filtration System and Cutting Oil Filtration System.

A Centralized Filtration System has huge benefits over a Individual Filtration System.

Read MoreAluminium is vastly used in automobile components. Various operations like drilling tapping on such components generate large quantum of chips. Individual filtration system are prone to breakdowns and do not give required filtration levels resulting in low coolant life.

In a CFS, Dirty fluid along with chips is collected in the dirty tank. This tank has a continuously moving scarper conveyor which removes the chips that settle down. A rotating mesh drum is placed inside this tank. The fluid passes through the mesh drum while the chips are separated on the outside. The filtered fluid drops into a clean tank. Clean fluid pump supply pressurized fluid to the machines. Sizing of the tanks, mesh drum and pumps is done based on your total flow requirement. In addition fine filter housing can be provided for through spindle coolant.

Read MoreSteel because of its ductile and tensile strength is widely used in auto component industry. But steel machining generally generates long curly chips. These chips are difficult to handle and donot flow with the help of pressurized coolant flow. Due to this restriction making a CFS was always a challenge.

Veeraja has now developed a unique chip cutter which can be attached to the outlet of individual chip conveyor of each machine. This chip cutter shreds the steel chips ( watch video ) into smaller manageable size. These can now be conveyed using traditional methods of gradient gravity flow.

Read MoreCast Iron is used for most major engine components and motion transmission. Various operations like drilling tapping and turning on such components generate large quantum of chips. Indivisual filtration system are prone to breakdowns and donot give required filtration levels resulting in low coolant life.

In a CFS, Dirty fluid along with chips is collected in the dirty tank. This tank has a continuously moving scarper conveyor which removes the chips that settle down. The coolant then passes through drum type magnetic seperators mounted on the side walls of the scraper conveyors. This ensures that the complete flow passes through a dense magnetic grid. The filtered fluid drops into a clean tank. Clean fluid pump supply pressurized fluid to the machines. Sizing of the tanks, magnetic drums and pumps is done based on your total flow requirement. In addition fine filter housing can be provided for through spindle coolant.

Read MoreGrinding process is used to generate better surface finish on components. Alongwith the removal of metal particle, the grinding wheel is also consumed. If proper filtration is not provided these particles escape the filtration system and generate scratch marks on the surface deteriorating the Ra and Rz values. The particles also clog the grinding wheel, which needs to re-dressed frequently. This increases the consumption of the grinding wheel.

A CFS for Grinding process is sized based on wheel grit size, viscosity of fluid and material of component. As the viscosity increases or the grit size becomes finer, the flow velocity through filter media has to be reduced to achieve desired results.

Read More

Honing is a very material removal process used to generate better surface finish on components. If proper filtration is not provided these particles escape the filtration system and generate scratch marks on the surface deteriorating the Ra and Rz values.

A CFS for Honing process is sized based on grit size, viscosity of fluid and material of component. As the viscosity increases or the grit size becomes finer, the flow velocity through filter media has to be reduced to achieve desired results.

Read More

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems